Unveiling the Precision: China’s Die Cast Tooling Dominance

Die cast tooling stands as the backbone of precision manufacturing, ensuring the creation of complex metal components with unparalleled accuracy. In the global landscape, China has emerged as a powerhouse in the die cast tooling industry, boasting technological prowess and cost-effectiveness. In this comprehensive exploration, we delve into the intricacies of China’s die cast tooling, understanding its components, industry dynamics, and the myriad advantages it offers to businesses worldwide.

I. Key Components of Die Cast Tooling:

A. Mold Design and Construction:

Precision in die cast tooling begins with meticulous mold design. China’s die cast tooling industry places a paramount emphasis on crafting molds with intricate detailing to meet the diverse needs of manufacturers. Engineers employ cutting-edge technologies to ensure the precision required for complex components. The materials used in these molds are carefully selected, emphasizing durability and longevity.

B. Die Casting Machines:

China has embraced diverse die casting machines, from conventional to state-of-the-art technologies. The industry has witnessed significant advancements, with the integration of automation, robotics, and digital controls. This not only enhances efficiency but also positions China at the forefront of die casting technology on a global scale.

II. China’s Die Cast Tooling Industry:

A. Growth and Development:

The trajectory of China’s die cast tooling industry reflects a remarkable journey of growth and development. Historical perspectives showcase a rapid evolution, with current market trends indicating sustained innovation and adaptability. The industry has become a key player in the global market, with China being a major hub for die cast tooling solutions.

B. Key Players in China:

Prominent die cast tooling companies in China have become trailblazers in the industry. Case studies of successful projects underscore the capabilities of these companies, showcasing their ability to deliver high-quality molds and components for diverse applications. Their expertise and technological prowess contribute significantly to China’s leadership in die cast tooling.

III. Advantages of Choosing China for Die Cast Tooling:

A. Cost-Effectiveness:

The economic advantage of choosing China for die cast tooling is evident in comparative cost analyses. The cost-effectiveness stems from efficient production processes, competitive labor costs, and economies of scale. Businesses can achieve significant savings without compromising on quality.

B. Technological Expertise:

China’s die cast tooling industry is marked by continuous innovation and technological expertise. Engineers and technicians undergo rigorous training, staying abreast of the latest advancements. This not only ensures the delivery of high-quality molds but also positions China as a global leader in die casting technology.

IV. Challenges and Considerations:

A. Quality Assurance:

Ensuring precision and consistency is a crucial aspect of die cast tooling. China’s industry is mindful of the need for stringent quality assurance measures, implementing robust testing protocols to meet international standards. Businesses, however, need to collaborate closely with suppliers to ensure their specific quality requirements are met.

B. Intellectual Property Concerns:

While China’s die cast tooling industry excels in innovation, businesses must navigate intellectual property concerns. Striking a balance between collaboration and protection is imperative, and companies should explore legal avenues to safeguard their innovations and designs.

V. Future Outlook:

A. Emerging Trends in Die Cast Tooling:

The future of die cast tooling in China is characterized by emerging trends that align with global shifts. Continuous technological advancements, such as the integration of artificial intelligence and sustainable practices, will shape the landscape. The industry is poised for growth and adaptation to meet evolving market demands.

B. Opportunities for Collaboration:

Global partnerships present significant opportunities for collaboration in die cast tooling. China’s expertise, combined with international market insights, creates a conducive environment for businesses to explore joint ventures and research initiatives. Identifying potential areas for collaboration can lead to mutually beneficial outcomes.

VI. Conclusion:

In summary, China’s die cast tooling industry stands as a beacon of precision and efficiency. Businesses looking to leverage cost-effective solutions without compromising on quality will find an ideal partner in the evolving landscape of Chinese die cast tooling. As the industry continues to innovate, opportunities for collaboration and growth abound, making China a definitive destination for die cast tooling excellence.

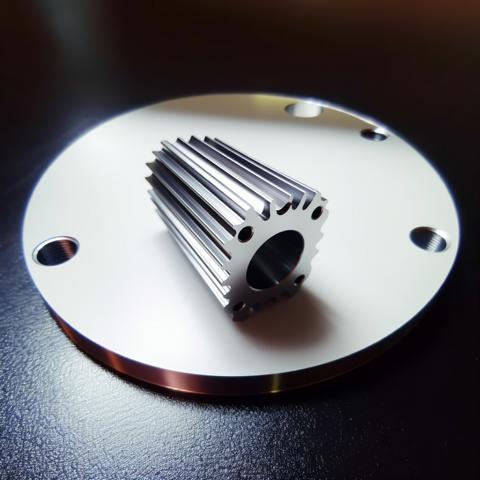

Are you in need of high-quality aluminum die casting services? Look no further than CNM Tech China die casting manufacturer! Our team of experts specializes in aluminum, zinc, and magnesium die casting, as well as machining parts, metal stamping, and plastic molds making.

With over 18 years of experience, you can trust that our die casting products are exemplary and cost-effective. We employ advanced equipment and machinery to ensure the highest quality solutions.

We have been made many type of aluminum die casting, zinc die casting, magnesium die casting from flow meter housing and valves to lighting fixture parts, automobile parts, and decorative hardware, we manufacture a wide range of products to meet your needs. And, as an added bonus, we also export various aluminum casting, zinc die casting, and magnesium casting products, as well as machining parts and injection molded parts.

Don’t settle for subpar aluminum casting services. Choose CNM Tech die casting China manufacturer for exceptional quality and affordable prices. Contact us today to learn more about our services and how we can help meet your die casting needs!